Organ blower modification

Christ Memorial Church, Williston, Vermont, USA

The old Spencer 1/2HP "Century" motor was causing continual starting

trouble because the brush assembly would not reliably pull away from

the radial commutator at the back of the motor. The brush assembly would

sit there, half engaged, generating much light and ozone, with the motor

running half speed and the organist wondering why everything was out of

tune. After many attempts to clean the unit and adjust the spring loading,

I finally decided to replace the motor. Because there are no motors available

with a 16 inch shaft, I constructed a pulley-driven jackshaft assembly that

uses a much smaller 3/4HP furnace blower motor.

Original motor and blower

Click on photo to display full size.

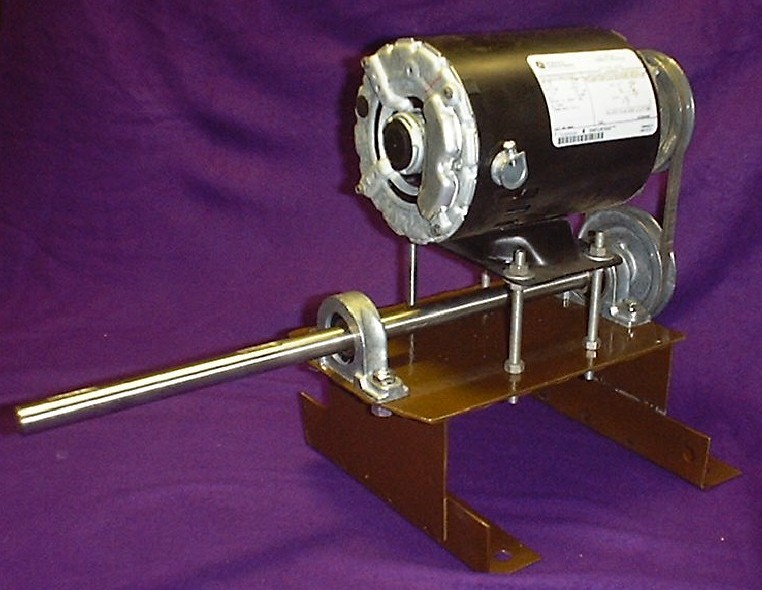

New motor assembly

Same bolt pattern, shaft location, shaft length as Century motor.

Yes, it's belt-driven, but this is not a maintenance problem if

the curator is sitting in the pew every Sunday morning.

Motor, pulleys, pillow blocks, and jackshaft are from

Grainger.

Threaded rod and steel plate were from my inventory.

Looking back, there were only two problems encountered in the

15 years of operation, both easily solved:

- Pulley set screw loosening.

- Motor thermal switch tripping after hours of continuous use.

Click on photo to display full size.