My exhaust pipe unexpectedly broke away from the engine while motoring in to the dock to replace the engine mounts under my 5411 diesel. Not bad timing, actually. I ended up replacing both exhaust system and engine mounts at the same time.

I was tired of hearing from well-meaning boaters that my "water pump impeller is damaged," tired of smelling the exhaust mist that follows the boat, tired of the grime on the transom that builds up so quickly, and tired of the hot exhaust pipe that raises engine compartment temperature, so I completely reconfigured the exhaust and cooling system.

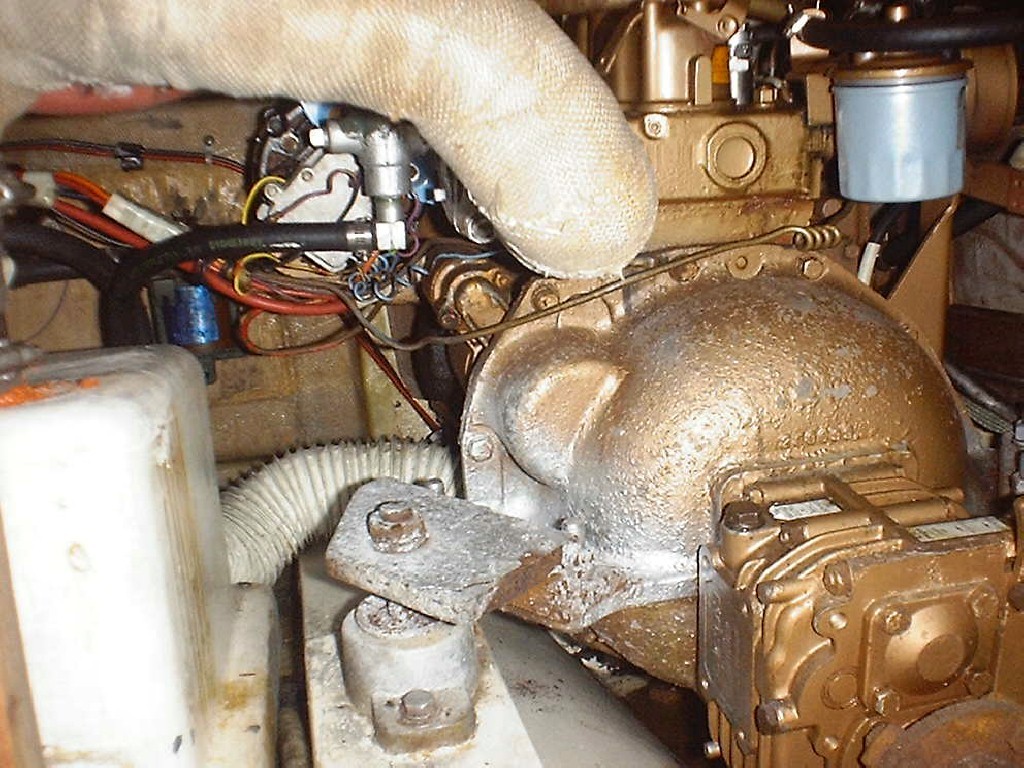

The photos reveal a three or four inch inch rise in this original exhaust pipe. When added to the subsequent drop into and inside the original muffler, the total drop to the water level in the muffler may have been ten or more inches.

The riser, when unwrapped, was in bad shape. When dropped on a concrete floor it shattered into fragments. The fiberglass insulation wrap had covered up the true condition. I suspect the pipe had been leaking for awhile if the grime in and around the engine compartment was any indication.

A crowbar easily removed the stock Catalina muffler.

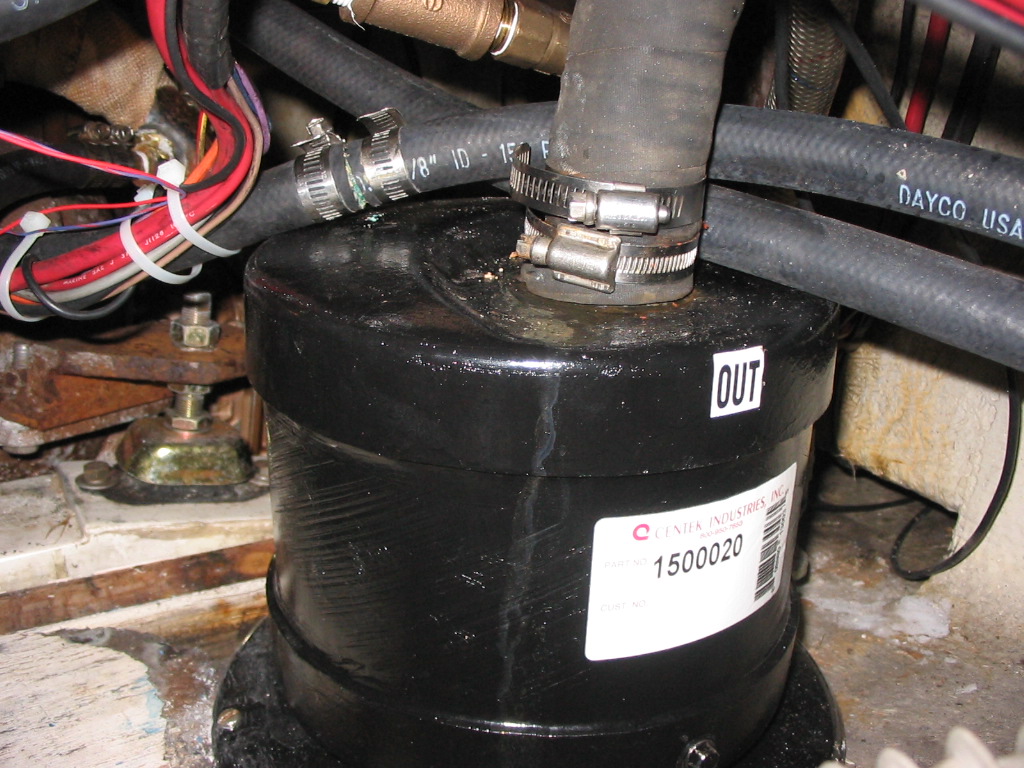

The Vernalift #1500020 muffler was installed on the bed of the old muffler. Two stainless screws hold its flange in place.

Vernalift side-in-top-out muffler. 1-5/8" inlet and outlet ports.

The 1-5/8" outlet port nicely fit the existing outlet hose. It was as simple as tightening the two stainless hose clamps on the hose.

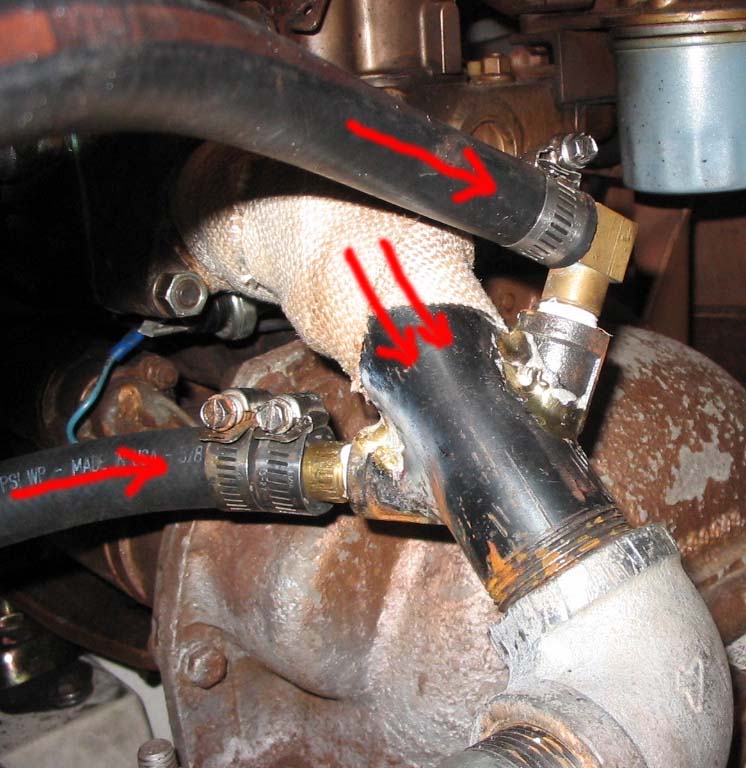

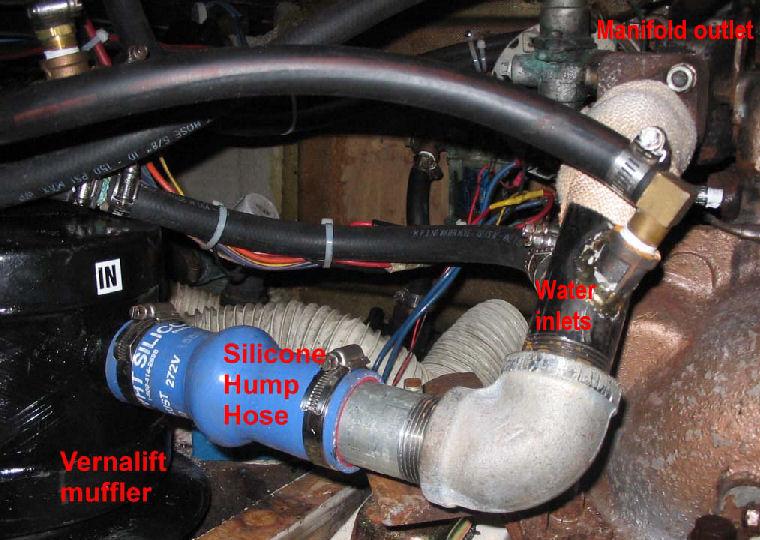

I installed new galvanized pipes from engine to muffler. The manifold outlet has a short nipple and 45° elbow followed by a sloped five-inch nipple, 90° elbow, and horizontal four-inch nipple (all 1-1/4" standard plumbing parts) aiming toward the muffler inlet. I wrapped fiberglass tape around the first several inches of pipe between engine and water inlets.

An alternative configuration could provide more design margin by adding a riser section. It would still fit with within the height of the compartment:

The gap between pipe and muffler is bridged by a six-inch 1-5/8" I.D. silicone hump hose obtained from Catalina Direct.

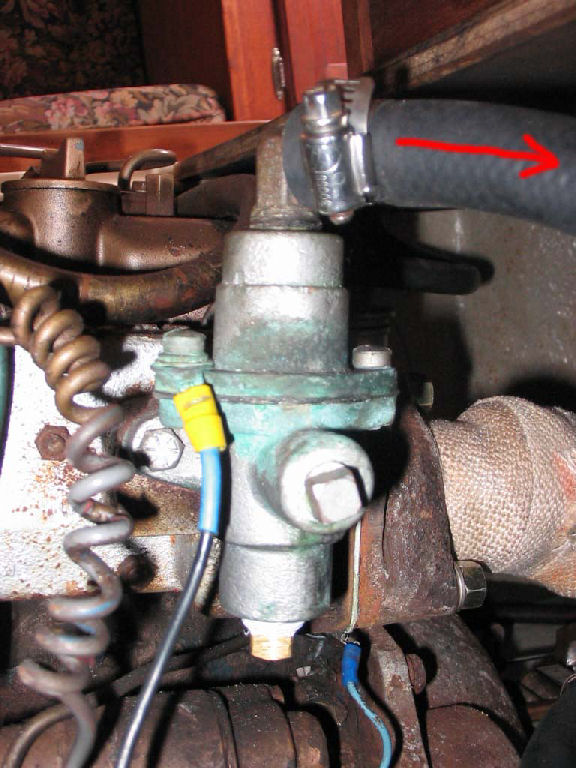

I brazed two water inlet ports on the sloped five-inch nipple, so water is injected immediately on the downslope from the engine, not just prior to the muffler as on the original system.

This is the total system of manifold outlet (wrapped in fiberglass tape due to heat,) galvanized pipes, water injection, silicone hump hose, and muffler.

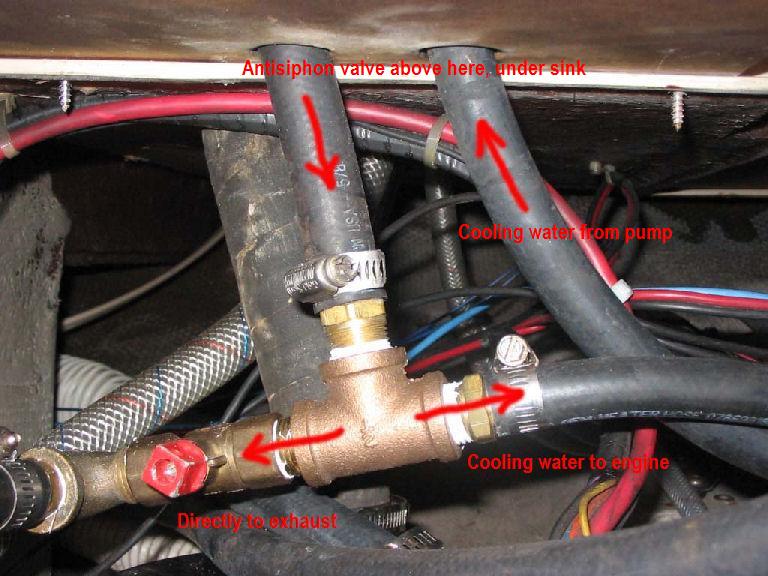

I removed the original "recirculation tee" on the thru-hull and installed a single hose barb. I hosed from there to the inlet strainer, from there to the water pump inlet, and from the water pump outlet up to the anti-siphon valve under the sink. Since leaks or breaks in that much of the system could sink the boat, I used reinforced hose and made these three runs short and protected as much as possible.

I checked and cleaned the anti-siphon valve in light of another Catalina owner's experience in which he removed and reinstalled his galley cabinet but never secured the anti-siphon valve back to inside. When he heeled enough for that plumbing to be below the water line his cylinders filled with water. That caused hydrolock and necessitated a complete oil change. Don't ignore the location and operation of the anti-siphon valve. In particular remove the rubber valve itself and ensure that it's not stuck shut due to age or crud.

On the outlet side of the anti-siphon valve I routed the hose back down to a tee.

This solution and configuration is probably not for everybody. Your mileage may vary.